THE ACTIONS WE TAKE

From our products to our facilities and our processes in between, we’re purposeful in the choices we make today toward a greater collective impact tomorrow. Learn more about this work and see what inspires us to evolve our environmentally sustainable efforts.

OFFSETTING OUR PLASTIC FOOTPRINT

Every year, an estimated total eight million metric tons of plastic enter the ocean—that’s equivalent to a garbage truck of plastic every minute.1 By preventing plastic’s diversion into nature,*2 we’re making a meaningful, measurable difference through plastic neutrality.

Through our partnership with Plastic Bank, we offset a portion of our plastic footprint1 and improve the livelihoods of thousands of collection members in hundreds of communities.1,3

As we work to offset waste from our products and packaging that cannot yet be reclaimed,*2 innovators like Carol Herring have a pivotal impact.

Aldo Zucaro serves as CooperVision’s sustainability champion - identifying and uncovering new sustainability opportunities and strategies that help to decrease CooperVision’s footprint.

Paul Riggs plays a crucial role in progressing our sustainability efforts across CooperVision and around the world, as he strives to find areas in which to minimize our possible environmental impact and support People + Planet.

CHAMPIONING HIGHER STANDARDS FOR PLASTICS

Through our efforts to offset and recover plastic, we’re already taking strides to tackle one of its major challenges: disposal.† We’re now taking steps to address how plastic is made, by focusing on our plastic suppliers and how the plastic we buy is produced.

By beginning to purchase ISCC PLUS-certified plastic, CooperVision is committed to achieving a higher standard for how plastics are made.§1

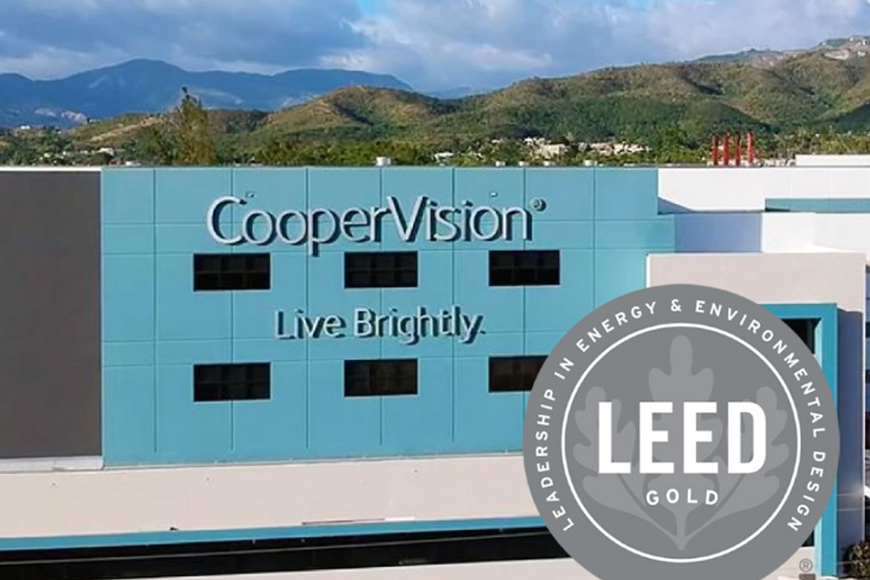

CERTIFICATIONS AND AWARDS

From conservation efforts in Puerto Rico to earning LEED Gold certification in Costa Rica and receiving a BREEAM-certified “Excellent” rating in the United Kingdom, we’ve been recognized for our ongoing dedication to sustainability in the many places we do business:

- Alajuela, Costa Rica - LEED Gold Certified

- Madrid, Spain - LEED Certified

- Coyol, Costa Rica - LEED Gold Certified

- Juana Diaz, Puerto Rico - LEED Gold Certified

- Scottsville, NY - LEED Silver Certified

- West Henrietta, NY - LEED Silver Certified

- Mount Park, UK - BREEAM Certified

A brighter tomorrow starts with all of us, today.

* Refers to CooperVision's plastic neutrality initiative with Plastic Bank.

† Through our partnership with Plastic Bank.

‡ According to peer-reviewed papers, polypropylene (PP) made using renewably sourced inputs yields a lower carbon footprint. Coopervision’s plastic supplier has found that manufacturing PP using fossil-based inputs produces 1.63 kg CO2e/kg PP whereas manufacturing ISCC-certified inputs produces -0.82 kg CO2e/kg PP.

§ ISCC PLUS: International Sustainability and Carbon Certification PLUS.

References:

1. CVI data on file, 2024.

2. CVI data on file, 2023.

3. CVI data on file as of 1/2024.

4. CVI data on file, 2023. Cradle-to-gate assessment of our supplier’s biorenewable input.

5. Narayan, R. (2011). Carbon footprint of bioplastics using biocarbon content analysis and life-cycle assessment. MRS Bulletin, 36(09), 716?721. https://doi.org/10.1557/mrs.2011.210.